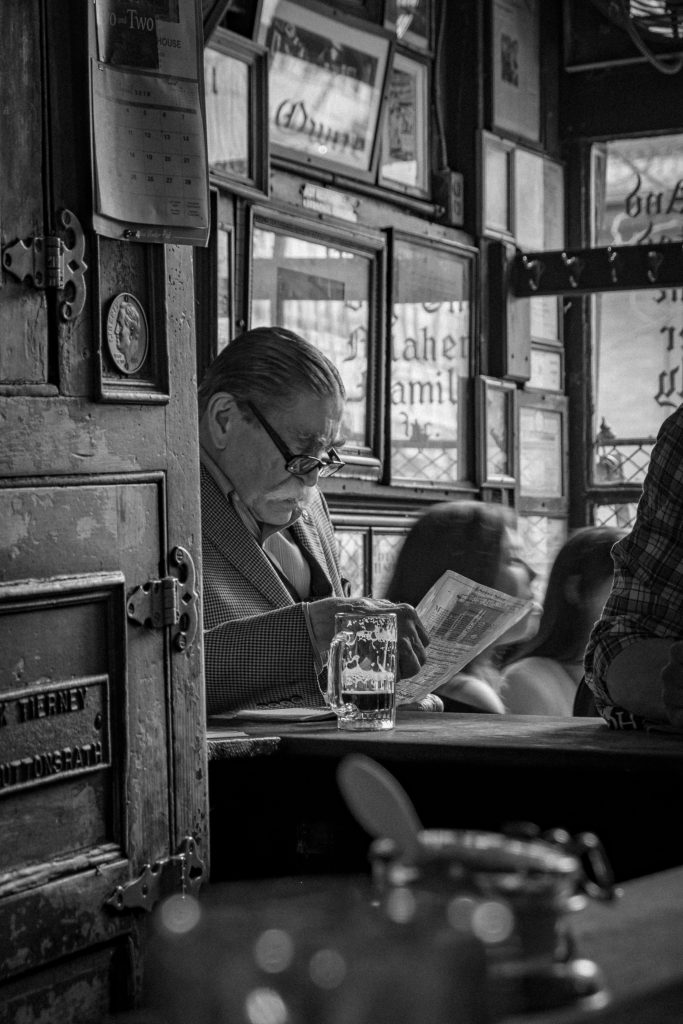

Imagine yourself sitting at a bustling pub, holding a cold glass of refreshing beer. Have you ever wondered what makes that beer so irresistibly fizzy and effervescent? In this article, we will take a closer look at the intriguing process behind the bubbles in beer, uncovering the secrets of carbonation that add that extra sparkle to your favorite brew. So, sit back, relax, and get ready to discover the fascinating world behind the bubbles in your pint.

The Importance of Carbonation in Beer

Beer is a beloved beverage all around the world, enjoyed by many for its complex flavors and refreshing qualities. One crucial aspect of beer that greatly impacts its taste and overall experience is carbonation. Whether it’s the burst of bubbles on your tongue, the smooth mouthfeel, or the effervescent aroma, carbonation plays a vital role in enhancing every sip of beer. In this article, we will delve into the world of carbonation in beer, exploring its significance in flavor and aroma, its impact on mouthfeel, and its contribution to the aesthetic appeal of this beloved beverage.

Enhancing Flavor and Aroma

Carbonation is more than just fizz; it significantly contributes to the overall flavor profile of beer. When carbon dioxide (CO2) is dissolved in beer, it creates carbonic acid, which, in moderation, provides a pleasant acidity and tanginess. This acidity can brighten up flavors, accentuate hop bitterness, and add a refreshing quality to the beer. Additionally, the release of carbon dioxide during the carbonation process helps to release volatile aromas, intensifying the aromatic experience of the beer. These enhanced flavors and aromas make carbonation an indispensable component in the enjoyment of beer.

Creating a Smooth Mouthfeel

Carbonation has a profound impact on the mouthfeel of beer. The bubbles of carbon dioxide not only provide a pleasing sensation on the palate but also contribute to the perceived body and texture of the beer. Proper carbonation can create a delicate effervescence that lifts the flavors and gives the beer a light, refreshing feel. It adds liveliness and vibrancy to the beer, making it more enjoyable and satisfying to drink. The way carbonation contributes to the mouthfeel of beer is an essential element to consider when striving for a well-rounded and pleasurable drinking experience.

Aesthetic Appeal

Beyond taste and mouthfeel, carbonation plays a significant role in the visual presentation of beer. The effervescence created by carbonation generates a lively display of bubbles that rise and cascade through the beer, creating an appealing and enticing spectacle. The presence of carbonation contributes to the formation of a frothy and resilient head, which not only enhances the appearance of the beer but also provides additional aromatics. A well-carbonated beer with an attractive head and lively bubbles is visually appealing, inviting the drinker to indulge in its deliciousness.

Understanding the Carbonation Process

To appreciate the importance of carbonation in beer, it is essential to grasp the different processes involved in carbonating beer. There are two primary methods of carbonation: natural carbonation and forced carbonation. Each method offers unique benefits and considerations, influencing the final characteristics of the beer.

Natural Carbonation

Natural carbonation, also known as bottle conditioning, involves a process of fermentation in which the beer carbonates itself over time. During natural carbonation, the beer undergoes both primary and secondary fermentation, allowing the yeast to produce carbon dioxide naturally.

Forced Carbonation

Forced carbonation, on the other hand, is a more controlled and expedited method of carbonating beer. This process involves the application of external carbon dioxide to the beer, typically done through kegging or bottling techniques.

Primary Fermentation

In the natural carbonation process, the primary fermentation is the initial stage in which the yeast consumes the fermentable sugars present in the beer wort. This process creates alcohol and a limited amount of carbon dioxide. At this stage, the carbonation levels are typically low, emphasizing the production of alcohol and establishing the foundation of the beer’s flavor.

Secondary Fermentation

Following the primary fermentation, the beer undergoes a secondary fermentation. During this phase, the beer is transferred to a secondary vessel, allowing the yeast to continue conditioning and evolve the beer further. The secondary fermentation is crucial for natural carbonation as it gives the yeast an opportunity to consume any remaining fermentable sugars, producing more carbon dioxide in the process.

Natural Carbonation

Natural carbonation, or bottle conditioning, is a traditional and time-tested method of carbonating beer. It relies on the residual yeast in the beer to consume additional fermentable sugars, producing carbon dioxide as a byproduct. This slow but effective process results in a natural and harmonious carbonation, often beloved by beer enthusiasts.

Conditioning Stage

During the conditioning stage of natural carbonation, the beer is placed in a bottle, allowing the remaining yeast to consume any leftover sugars. The carbonation process can take several weeks or even months, depending on various factors such as temperature and yeast activity. The extended conditioning period allows for the gradual and controlled carbonation development, ensuring a well-rounded and balanced final product.

Yeast Consumption of Fermentable Sugars

The yeast’s consumption of fermentable sugars is a critical step in the natural carbonation process. As the yeast metabolizes these sugars, it produces carbon dioxide as a natural byproduct. This slow release of carbon dioxide within the sealed bottle leads to the accumulation of pressure, transforming the beer into a carbonated beverage.

CO2 Production

The production of carbon dioxide creates the desired effervescence in the beer. Carbonation levels can be influenced by various factors such as the amount of remaining fermentable sugars, yeast strain, and temperature. The controlled production of carbon dioxide during the natural carbonation process ensures that the beer achieves a suitable level of carbonation, providing an optimal drinking experience.

Interaction with Alcohol Content

The interaction between carbonation and alcohol content is a significant aspect of beer production. As the yeast consumes fermentable sugars and converts them into alcohol, the carbon dioxide produced can either dissolve into the beer or create bubbles, depending on the pressure and temperature conditions. The balance between alcohol content and carbonation is crucial in achieving a well-integrated and enjoyable drinking experience.

Forced Carbonation

Forced carbonation offers a more controlled and efficient method of carbonating beer. With forced carbonation, brewers can achieve consistent carbonation levels, reduce fermentation time, and have greater control over the overall carbonation process.

Application of External CO2

In forced carbonation, external carbon dioxide is applied to the beer to achieve the desired carbonation level. This is typically done by introducing the beer into a sealed vessel and pressurizing it with carbon dioxide. By directly adding carbon dioxide to the beer, brewers have greater control over the carbonation process and can achieve precise levels of carbonation.

Kegging and Bottling Techniques

Forced carbonation is commonly utilized in kegging and bottling processes. In kegging, beer is carbonated by pressurizing the keg with carbon dioxide, allowing the gas to dissolve into the beer over time. This method provides brewers with the ability to carbonate large volumes of beer efficiently. In bottling, carbonation can be achieved through counter-pressure filling, which helps maintain the carbonation levels during the bottling process.

Consistency and Control

One of the most significant advantages of forced carbonation is the ability to achieve consistent carbonation levels across multiple batches of beer. By precisely controlling the amount of carbon dioxide introduced, brewers can replicate the desired carbonation level for each batch. This consistency ensures that consumers can expect a similar drinking experience with each bottle or keg.

Decreased Fermentation Time

Forced carbonation offers the advantage of reduced fermentation time compared to natural carbonation. By introducing carbon dioxide directly into the beer, brewers can bypass the secondary fermentation phase and achieve carbonation more quickly. This expedited process allows for a faster turnaround time, making forced carbonation beneficial for large-scale commercial breweries and homebrewers alike.

Primary Fermentation

The primary fermentation stage plays a crucial role in the carbonation process. During this stage, yeast activity is at its peak as it consumes fermentable sugars, producing alcohol and a limited amount of carbon dioxide. While primary fermentation is primarily focused on alcohol production, it sets the stage for future carbonation.

Yeast Activity

Yeast plays a vital role in the primary fermentation of beer. As the yeast consumes the fermentable sugars present in the beer wort, it undergoes metabolic processes that produce alcohol and carbon dioxide. The vigorous yeast activity during this stage sets the foundation for the beer’s flavor and carbonation potential.

Sugar Consumption

As yeast consumes fermentable sugars, it converts them into alcohol and carbon dioxide. The balance between sugar consumption and yeast metabolism is crucial in determining the final alcohol content and carbonation levels of the beer. Proper management of sugar consumption during primary fermentation contributes to achieving a well-rounded and balanced beer.

Production of Alcohol

The primary fermentation stage is primarily focused on alcohol production. The yeast converts fermentable sugars into alcohol through its metabolic processes. This production of alcohol is a crucial component of beer, contributing to its distinct flavor and character.

Limited Carbonation

While a small amount of carbon dioxide is produced during primary fermentation, the carbonation levels of the beer at this stage are typically limited. The purpose of primary fermentation is to establish the alcohol content and lay the groundwork for future carbonation during secondary fermentation or forced carbonation methods.

Secondary Fermentation

After the completion of primary fermentation, beer can undergo a secondary fermentation stage. This phase further develops the flavors, carbonation, and clarity of the beer, resulting in a more refined and well-rounded product.

Transfer to a Secondary Vessel

During the secondary fermentation stage, the beer is transferred to a secondary vessel. This vessel can be another fermentation vessel or a specialized vessel designed to facilitate conditioning and aging. The transfer helps to separate the beer from the trub, allowing for clarification and reducing the risk of off-flavors.

Yeast Conditioning

In secondary fermentation, the yeast continues to condition the beer. Although primary fermentation is complete, residual yeast remains in suspension, contributing to further flavor development and carbonation. The yeast consumes any remaining fermentable sugars, producing additional carbon dioxide, which contributes to the beer’s carbonation levels.

Carbonation Enhancement

The secondary fermentation stage is crucial for enhancing carbonation in bottle-conditioned beers. With the help of the yeast, the beer naturally carbonates itself over time. This slow and controlled carbonation enhances the drinking experience, providing a pleasant and effervescent mouthfeel.

Clarification

In addition to carbonation and flavor development, the secondary fermentation stage also promotes clarification of the beer. As the beer settles in the secondary vessel, residual solids and unwanted particles precipitate to the bottom, creating a clearer and more visually appealing product. The removal of these unwanted elements enhances the overall aesthetic appeal of the beer.

Factors Affecting Carbonation

Several factors can affect the carbonation levels and characteristics of beer. Understanding these factors is crucial for brewers seeking to achieve the desired carbonation profile and ensure a consistent and enjoyable drinking experience.

Yeast Strains and Fermentation Temperature

Different yeast strains possess varying capabilities and characteristics when it comes to carbonation. Some strains are more efficient in consuming fermentable sugars and producing carbon dioxide, resulting in higher levels of carbonation. The fermentation temperature also affects yeast activity and carbonation levels, with higher temperatures often leading to faster fermentation and potentially higher carbonation.

Sugar Type and Amount

The type and amount of fermentable sugars added to the beer directly influence carbonation levels. Brewers must carefully select the sugar types and quantities to achieve the desired carbonation outcome. Different sugars, such as sucrose, dextrose, or maltose, can yield varying levels of carbonation. Additionally, the amount of sugar added during priming or kegging determines the level of carbonation achieved.

Pressure and Temperature during Secondary Fermentation

During secondary fermentation or forced carbonation, both pressure and temperature play crucial roles. Higher pressure and lower temperatures generally result in higher levels of carbonation. Brewers must carefully manage these variables to achieve the desired carbonation levels without compromising the taste and quality of the beer.

Age and Condition of Yeast

The age and condition of the yeast employed in the carbonation process also impact carbonation levels. Fresh and healthy yeast will perform more efficiently, consuming fermentable sugars and producing carbon dioxide. It is essential for brewers to maintain yeast health and viability to ensure consistent and reliable carbonation in their beers.

The Role of Yeast

Yeast, as the powerhouse behind fermentation, plays a critical role in the carbonation process. Understanding yeast metabolism, flocculation, and yeast health is essential for brewers striving to achieve optimal carbonation in their beers.

Yeast Metabolism and CO2 Release

During fermentation, yeast metabolizes fermentable sugars, converting them into alcohol and carbon dioxide. The carbon dioxide released by the yeast is responsible for the carbonation in beer. Understanding and managing yeast metabolism is crucial in controlling the carbonation levels and achieving the desired flavor profile of the beer.

Flocculation and Sedimentation

Flocculation refers to the process in which yeast cells clump together and settle to the bottom of the fermentation vessel. This settling is essential for clarity and the removal of unwanted solids. Proper flocculation ensures that yeast sediment is consolidated, reducing the risk of off-flavors and contributing to the appearance of the beer.

Yeast Health and Carbonation Effects

Maintaining yeast health is vital for achieving consistent and desirable carbonation effects in beer. Healthy yeast has a higher metabolism, ensuring efficient sugar consumption and carbon dioxide production. Proper yeast management and propagation techniques, such as proper pitching rates and maintaining ideal fermentation conditions, contribute to yeast health and ultimately impact carbonation quality.

Yeast Propagation for Consistent Carbonation

Maintaining a consistent yeast propagation and management process is crucial for ensuring consistent carbonation across multiple batches of beer. By carefully monitoring yeast health and vitality, brewers can achieve consistent and reliable carbonation levels, providing a consistent drinking experience with every bottle or keg.

Common Carbonation Techniques

To achieve desired carbonation levels, brewers employ several techniques suited to their brewing process and preferences. These techniques include bottle conditioning, force carbonation in kegs, counter-pressure filling, spunding, and cask conditioning.

Bottle Conditioning

Bottle conditioning, or natural carbonation, involves adding a small amount of fermentable sugar to the beer before bottling. The residual yeast consumes the added sugar, producing carbon dioxide and naturally carbonating the beer over time. This traditional technique offers the advantages of improved flavor development and complexity, as well as the potential for extended shelf life.

Force Carbonation in Kegs

Force carbonating beer in kegs allows for precise control over carbonation levels and is commonly employed by commercial breweries. By introducing carbon dioxide to a sealed keg, brewers can carbonate their beer quickly and consistently. Force carbonation in kegs offers convenience and efficiency and is often the preferred method for breweries aiming to maintain consistent carbonation across their product line-up.

Counter Pressure Filling

Counter-pressure filling is a technique used for carbonating beer in bottles or cans while minimizing oxidation and maintaining consistent carbonation levels. This method involves filling the container with carbonated beer under pressure to maintain carbonation while preventing the release of excess carbon dioxide during the filling process. Counter-pressure filling ensures that the beer remains carbonated during packaging, resulting in a more enjoyable drinking experience for consumers.

Spunding

Spunding, or natural fermentation carbonation, involves fermenting the beer in a pressurized vessel, such as a fermenter or keg. As the yeast consumes the fermentable sugars, it produces carbon dioxide, which pressurizes the vessel and naturally carbonates the beer. Spunding allows for a slower and more controlled carbonation process, often resulting in a smoother and more delicate carbonation profile.

Cask Conditioning

Cask conditioning is a traditional method of carbonating beer that involves fermenting and conditioning beer in a cask or barrel. The natural carbonation occurs as the remaining yeast consumes residual sugars and produces carbon dioxide, carbonating the beer. This technique is commonly used in British styles of beer, providing a unique and gentle carbonation profile.

Carbonation Troubleshooting and Tips

Carbonation can pose challenges for brewers, from issues of overcarbonation and undercarbonation to gushing and foaming problems. Additionally, maintaining the quality and freshness of beer during the carbonation process is crucial. Here are some troubleshooting tips to ensure optimal carbonation and beer quality.

Overcarbonation and Undercarbonation

Overcarbonation occurs when a beer contains excessive amounts of carbon dioxide, resulting in aggressive foaming and an unpleasant drinking experience. Undercarbonation, on the other hand, leaves the beer flat, lacking the desired effervescence and mouthfeel. To avoid these issues, brewers must carefully measure and control the amount of priming sugar or applied pressure during the carbonation process, adhering to recommended guidelines.

Gushing and Foaming Issues

Gushing and foaming during the pouring of beer can be frustrating for both brewers and consumers. These issues often stem from overcarbonation or the presence of contaminants such as wild yeast or excess protein. To combat gushing and foaming, brewers should pay attention to proper carbonation levels, cleanliness, and the use of appropriate glassware and pouring techniques.

Avoiding Oxygen Pickup during Carbonation

During the carbonation process, brewers must take precautions to minimize oxygen pickup. Oxygen exposure can lead to off-flavors, oxidation, and decreased shelf life. Proper purging of kegs or bottles with carbon dioxide, minimizing splashing during transfers, and maintaining airtight seals are crucial steps in preventing oxygen pickup and ensuring the quality of carbonated beer.

Proper Glassware and Pouring Techniques

Appropriate glassware and pouring techniques contribute to an optimal carbonation experience. Choosing the right glassware can enhance the visual presentation of carbonated beer and aid in releasing aromas. Additionally, employing proper pouring techniques, such as tilting the glass and pouring slowly, can minimize excessive foam and maximize the enjoyment of carbonated beer.

In conclusion, carbonation plays a crucial role in the enjoyment of beer. It enhances flavor and aroma, contributes to a smooth mouthfeel, and adds to the aesthetic appeal of this beloved beverage. By understanding the carbonation process, considering the different carbonation techniques, and troubleshooting any issues, brewers can create beers with the perfect balance of bubbles, flavor, and overall excellence. So next time you raise a glass of your favorite beer, take a moment to appreciate the carbonation dancing upon your palate and enhancing your overall beer-drinking experience. Cheers to the magic of carbonation!

© 2023 by brewandbeyond.com. All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written permission of brewandbeyond.com.